By Quincy Collins

Many budget-priced drill presses have a fair amount of runout, or play, especially as the quill is extended. Mine is no exception, so I headed to the internet to try to find a solution. The bulletin boards seemed to be filled with owners unhappy with the accuracy of their drill presses.

Some suggested flattening the splines with a hammer to reduce play, which seemed a little drastic to me. I then hit on this solution that has worked for me and is a little more elegant than taking a hammer to the drill press.

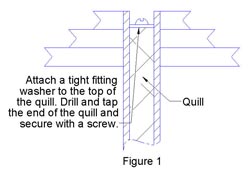

The upper end of my quill, where it passes through the pulleys, had a countersunk center mark. I simply drilled and tapped this location and used a screw to attach a custom washer (Figure 1). The washer was sized on the lathe for a close tolerance with the bore of the pulley shaft. This served to stabilize the quill at all points in its travel.

The spindle runout of my drill press has been greatly reduced and drilling is now a much happier and less frustrating job. I have limited shop time so it was nice to have found a solution that was both quick and easy.

Thanks, Quincy, your subscription has been extended by an issue!