By John Viggers

By John Viggers

I used this method to turn very small, decorative, circular ribs on the outside of some parts for a model. I could have ground the semicircular shape into a high-speed steel lathe cutter blank, but I think this method gave superior results.

I positioned an old carbide tip in a vise,with the central hole half exposed. Then, I snapped the tip in half by hitting it with a hammer. It broke through the hole, giving me two halves. I held one of the halves in a pair of locking pliers and ground the broken edge to an appropriate angle and shape on a diamond grinding wheel.

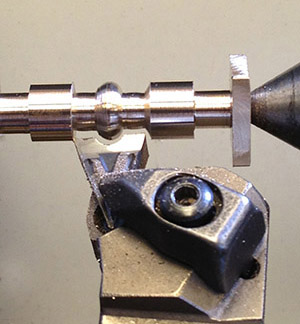

The tip was then held in a lathe toolholder, as shown in the photo, and used to turn the half-round rib on the small pieces. The result was smooth and uniform on four workpieces.

Carbide tips are very accurately manufactured, including the central hole, and there are many different hole diameters. The shape of the tip to be snapped needs to take into account how much tip will remain to be held.

Carbide tips are very accurately manufactured, including the central hole, and there are many different hole diameters. The shape of the tip to be snapped needs to take into account how much tip will remain to be held.

I chose a lozenge shape, and I was able to hold the fragment in a clamp-type tool. An alternative would be to braze or silver solder the fragment onto some square section bar.