By Paul Temple

The differential screw has been around for 200 years. You can Google “differential screw” to see how it gives fine movement by using two different thread pitches on one shaft. It’s a handy technique, since it’s easy to implement with standard taps and dies. Here, rather than for fine adjustment, I’ve used the differential screw as a fastener in two different ways.

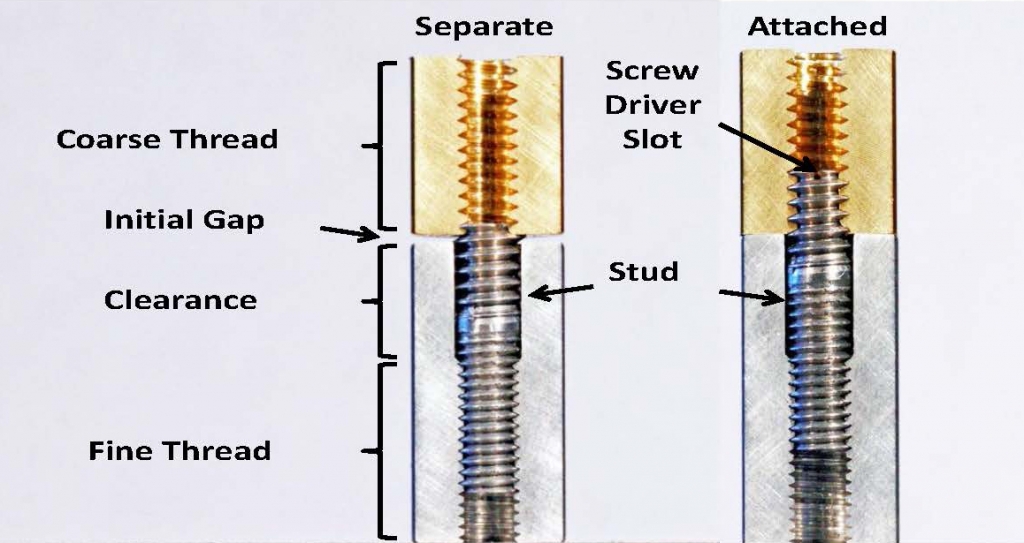

The photo shows a cut-away model of a differential screw fastener before (with ~ .060” initial gap) and after attachment. The clearance section of the 1/4-28 fine-threaded part contains the retracted stud as shown. When turned, the stud advances quickly into the 1/4-20 course-threaded part and exits the fine-threaded part at a slower rate, so the parts are gradually drawn tightly together with minimal screwdriver torque (this differential thread is the equivalent of a 70 TPI fastener). Neither part needs to be rotated, just the stud so, unlike the next application, multiple fasteners can be used on one part.

During one project I needed to attach a rectangular post to an optical table where the post had to be correctly oriented. The table had a grid of 1/4-20 blind tapped holes. I made a 1/4-20/28 stud and tapped a 1/4-28 blind hole into the bottom of the post, enlarging the hole for ~1/4” before the fine threads began. If I had access to the stud, I could have tightened it in place. Instead, I wrapped Teflon tape on the fine thread to give some resistance to turning. I screwed the stud into the post and then put the stud into the table. Unfortunately, when the post tightened against the table it wasn’t oriented correctly. Taking the post out and turning the stud to a small angle changed the final post orientation when put back into the table. It only took a few such trials to give the post orientation I wanted.

Thanks, Paul, your subscription has been extended by an issue!